What is EVA Foam Material and Its Properties?

2025-05-21

Table of Contents

- Introduction: Understanding EVA Foam

- What is EVA Foam?

- Key Properties of EVA Foam

- Applications of EVA Foam in Various Industries

- Fubo – Leading EVA Foam Manufacturer in China

- Advantages of Using EVA Foam

- EVA vs. Other Foam Materials

- Conclusion: Why EVA Foam is a Smart Choice

- Summary Table: EVA Foam Overview

Introduction: Understanding EVA Foam

EVA foam is one of the most widely used polymer foams in modern industries due to its lightweight, flexible, and resilient characteristics. From packaging electronics to sports equipment and toys, EVA foam has become a go-to material for engineers and product designers. In this article, we’ll explore the nature of EVA foam, its key properties, and why manufacturers like Fubo in Dongguan, China, rely on it to deliver high-quality solutions across sectors.

What is EVA Foam?

EVA stands for Ethylene-Vinyl Acetate. It is a closed-cell foam made by combining ethylene and vinyl acetate to form a copolymer. The result is a material that is:

- Rubber-like in flexibility

- Durable and resilient

- Lightweight yet strong

EVA foam is often used as a substitute for rubber or vinyl products due to its superior softness and versatility.

Key Properties of EVA Foam

EVA foam stands out because of its well-balanced physical and chemical properties. Below are the most important features:

1. Cushioning and Shock Absorption

- Absorbs impacts and protects against vibration damage

- Ideal for packaging fragile electronics or sports equipment

2. Flexibility and Elasticity

- Highly flexible without tearing or cracking

- Recovers shape after compression

3. Lightweight

- Low density reduces total product weight

- Perfect for wearable or portable applications

4. Water and Chemical Resistance

- Impermeable to water, suitable for marine or wet environments

- Resistant to oils, greases, and mild acids

5. Thermal Insulation

- Acts as a heat barrier in packaging and construction

6. Safe and Non-Toxic

- Non-toxic, BPA-free, and safe for children's toys

- Complies with international safety standards

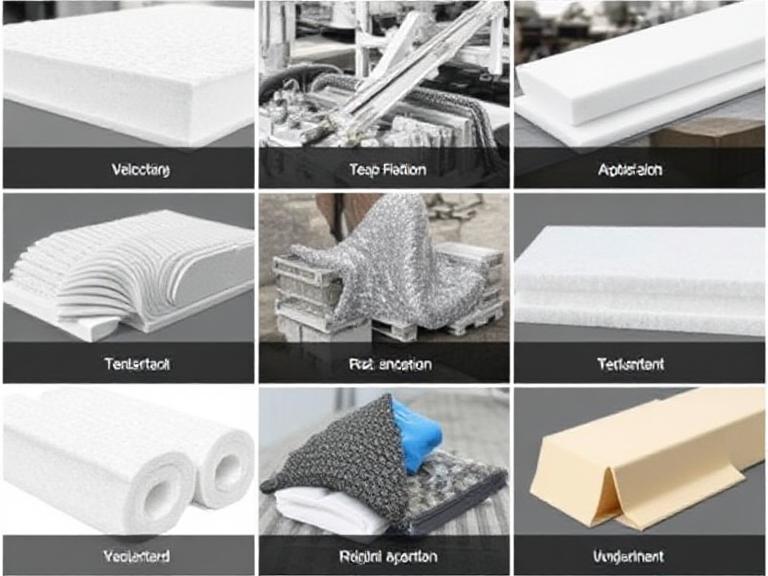

Applications of EVA Foam in Various Industries

Thanks to its adaptability, EVA foam is used in a wide range of products and sectors:

Electronics and Appliances

- Protective foam inserts for laptops, TVs, and mobile devices

- Shock-absorbing pads for delicate semiconductor components

Sports and Fitness

- Yoga mats, knee pads, helmets, and protective guards

- Swimming aids like EVA foam boards

Toys and Education

- Foam puzzles, number and letter blocks

- Safe and colorful materials for children’s playrooms

Packaging

- Custom foam cutouts for high-end or fragile products

- Protective liners for toolkits and electronics

Agriculture and Horticulture

- Soilless culture foam boards for hydroponic farming

Fubo – Leading EVA Foam Manufacturer in China

Fubo is a professional foam manufacturer located in Xiegang, Dongguan, Guangdong, offering advanced EVA foam solutions tailored to multiple industries. Here’s why Fubo stands out:

- Diverse Product Line: From EVA foam swimming boards to cushioning materials and soilless culture boards

- Fast Turnaround: Design drawings within 8–24 hours and sample delivery in just 1–3 working days

- OEM & Custom Solutions: Catering to electronics, semiconductors, sports, drones, and more

- Experienced Engineering Team: Over 30 skilled professionals ensure precise and innovative designs

- Quick Bulk Production: Orders shipped within 7–10 days

Fubo has collaborated with major enterprises, offering high-performance packaging and protection solutions for modern industries worldwide.

Advantages of Using EVA Foam

Using EVA foam in manufacturing or packaging can give your products a distinct edge. Here are the top advantages:

- Customizable: Easily molded, cut, and shaped to suit specific applications

- Durable: Long-lasting with excellent resistance to wear and tear

- Eco-Friendly Options: Available in recyclable and non-toxic variants

- Enhanced Safety: Soft and non-abrasive, minimizing injury risks

- Cost-Effective: Affordable solution without sacrificing quality

EVA vs. Other Foam Materials

How does EVA compare to other commonly used foams?

EVA vs. PU (Polyurethane) Foam

- EVA: More rigid and water-resistant

- PU: Softer and more porous but less durable in wet environments

EVA vs. PE (Polyethylene) Foam

- EVA: Better elasticity and color customization

- PE: More rigid and used mainly for structural purposes

EVA vs. Rubber

- EVA: Lightweight, more affordable, and non-marking

- Rubber: Heavy and costly but better for high-friction applications

Conclusion: Why EVA Foam is a Smart Choice

EVA foam offers a powerful combination of durability, safety, customization, and affordability. Its ability to withstand physical impact and environmental conditions makes it a reliable material for countless applications—from packaging to sports and agriculture.

If you’re searching for a dependable EVA foam manufacturer, Fubo in Dongguan is a trusted partner for businesses worldwide. With fast prototyping, expert technical support, and high-quality products, Fubo meets the needs of diverse sectors including electronics, semiconductors, and new energy.

Whether you need foam boards for hydroponics, EVA toys for educational use, or protective foam for packaging, EVA foam provides unmatched performance and flexibility.

Summary Table: EVA Foam Overview

| Aspect | Details |

|---|---|

| Material | Ethylene-Vinyl Acetate (EVA) Copolymer |

| Key Properties | Shock absorption, flexibility, water resistance, thermal insulation |

| Industries | Electronics, packaging, toys, sports, agriculture |

| Advantages | Customizable, durable, lightweight, safe, affordable |

| Manufacturer Highlight | Fubo – OEM foam producer with quick turnaround and global delivery |

| Sample Lead Time | 1–3 working days |

| Bulk Delivery | 7–10 working days |