High Density EVA Foam Sheets Wholesale: A Complete 2025 Buyer's Guide

2025-07-01

Table of Contents

- Introduction

- What Is High-Density EVA Foam?

- Fubo Foam Manufacturer Overview

- 1. Electronics & Hardware Packaging

- 2. Sports & Protective Equipment

- 3. Industrial & Appliance Cushioning

- 4. Custom Foam Inner Linings

- Key Advantages of High-Density EVA

- Wholesale Buying Tips

- Quality, Lead Time & Shipping

- Conclusion

- Summary Table

Introduction

High-density EVA (Ethylene‑Vinyl Acetate) foam sheets have become the go-to material for protective packaging, sports gear, electronics cushioning, and custom insulation across industries in 2025. Their excellent shock absorption, resilience, and customizability make them an ideal wholesale buy. This guide dives into uses, procurement best practices, and highlights Fubo Foam, a China-based specialist delivering fast OEM solutions and top-tier quality.

What Is High-Density EVA Foam?

EVA foam is a closed-cell, durable, lightweight material known for its combination of transparency, tensile strength, and flexibility. High-density grades are engineered to provide enhanced shock absorption, load-bearing capacity, and durability, making them suitable for aggressive environments like electronics shipping, tool protection, and industrial sealing.

Fubo Foam Manufacturer Overview

Based in Xiegang, Dongguan, Fubo manufactures high-density EVA sheeting and customized inner linings. Serving sectors like electronics, sports, drones, and appliances, they offer:

- OEM designs with fast turnaround: 8–24 hours for drawings, 1–3 days for samples

- Bulk delivery in ~7–10 days

- Collaboration with reputable global brands

- High-density EVA sheets for buffering and protection needs

This combination of speed and scale builds Fubo into a strong contender for high-volume wholesale orders—especially when customized foam inserts are needed.

1. Electronics & Hardware Packaging

High-density EVA foam is ideal for protecting electronic devices and hardware during transport and storage.

- Prevents shock and vibration damage in transit

- Clean, dust-free closed-cell structure preserves components

- Custom die‑cut liners for precise fit within boxes or trays

2. Sports & Protective Equipment

From skateboard pads to protective kneepads and helmets, EVA offers lightweight protection and comfort.

- High energy absorption in sports gear and padding

- Hygienic, mildew-resistant surface for repeated use

- Custom ergonomic cuts for better fit and comfort

3. Industrial & Appliance Cushioning

Used in power tools, vacuum cleaners, and drones to isolate vibrations and reduce part wear.

- Buffers moving parts and protects electronics

- Thermal stability protects sensitive machinery parts

- Resistant to oils and solvents for industrial settings

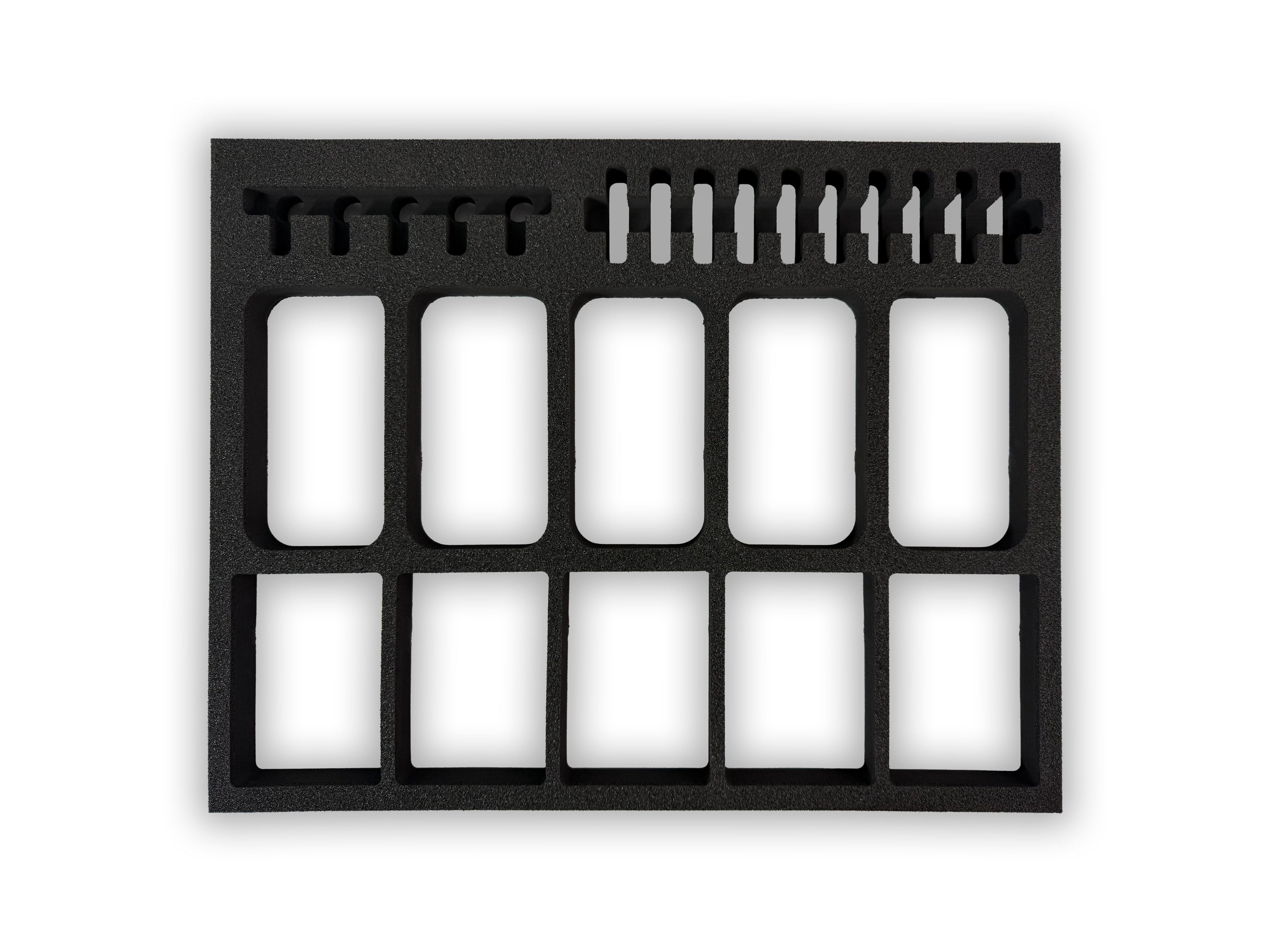

4. Custom Foam Inner Linings

For premium and protective packaging, custom inner liners prevent movement and damage inside shipping boxes or tool cases.

- Die cuts fit tools, components, or devices precisely

- OEM design support from concept to mass production

- Soft surface finish avoids scratches and abrasions

Key Advantages of High-Density EVA

- Superior Impact Resistance: Closed-cell structure minimizes shock

- Wide Hardness Range (Shore A 20–70+): adaptable to multiple needs

- Customizable: color, thickness, texture, die-cut form

- Environmental stability: resists moisture, UV, chemicals, and mold

- Cost-effective: Lightweight and easy to ship

Wholesale Buying Tips

1. Define Key Specs

- Thickness and density based on cushion or bearing requirements

- Physical dimensions and fabrication tolerance

2. Choose a Reputable Supplier

- Look for fast sample and design response like Fubo provides

- Factory certifications (ISO, material compliance) are critical

3. Clarify Custom Add-ons

- Check ability to die-cut, laminate, or add adhesive backing

- Specify color, surface texture (smooth, matte, EVA wave)

4. Order Planning

- Rapid prototyping for testing

- Estimate lead-time (7–10 days typical for bulk)

- Understand minimum order quantities and shipping terms

5. Packaging & Shipping

- Sheets to be flat-packaged with covers to avoid deformation

- Prefer sealed pallets or containers to maintain hygiene

Quality, Lead Time & Shipping

Fubo Foam stands out by combining quality with speed. Their design-to-sample timeframe of 1–3 days and bulk fulfillment within 7–10 days suits tight production calendars. For international buyers, ensure packaging practices consider long transit, humidity, and customs handling.

Conclusion

High-density EVA foam sheets offer unmatched versatility—from protecting electronics to cushioning sports equipment. For wholesale needs in 2025, Fubo provides fast, high-quality OEM service with robust production capacity. When sourcing, prioritize material specs, customization options, and supplier reliability to ensure the best ROI and product performance.

Summary Table

| Aspect | Fubo Strengths | Your Consideration |

|---|---|---|

| Material Quality | High-density EVA, consistent buffering | Select density and hardness based on use |

| Customization | Fast design/samples, OEM cutting/lining | Define shape, thickness, and texture early |

| Speed | Samples in 1–3 days; bulk in 7–10 | Plan timing with production cycles |

| Certifications | Factory standards, foreign customer base | Verify quality and manufacturing standards |

| Price & MOQ | Competitive pricing, large output | Balance MOQ vs unit price for best value |

| Logistics | Export-ready packaging | Clarify shipping method and customs docs |