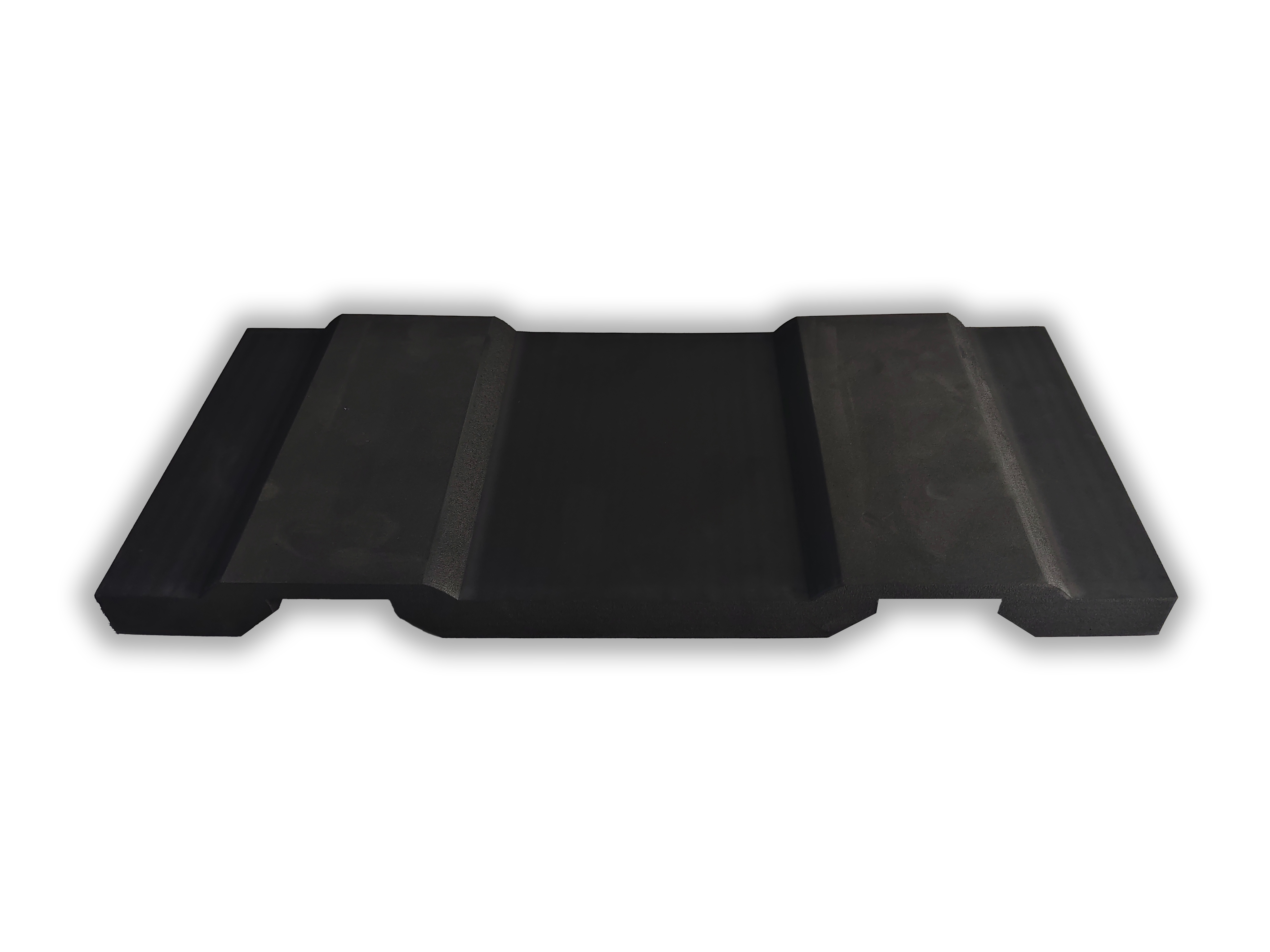

When transporting or storing sensitive equipment, even minor impacts can lead to costly damage. That’s where precision-engineered Black EVA Foam solutions come in. Unlike generic foam padding, our custom CNC-cut inserts are designed to match your equipment’s exact dimensions, offering unmatched shock absorption and vibration dampening.

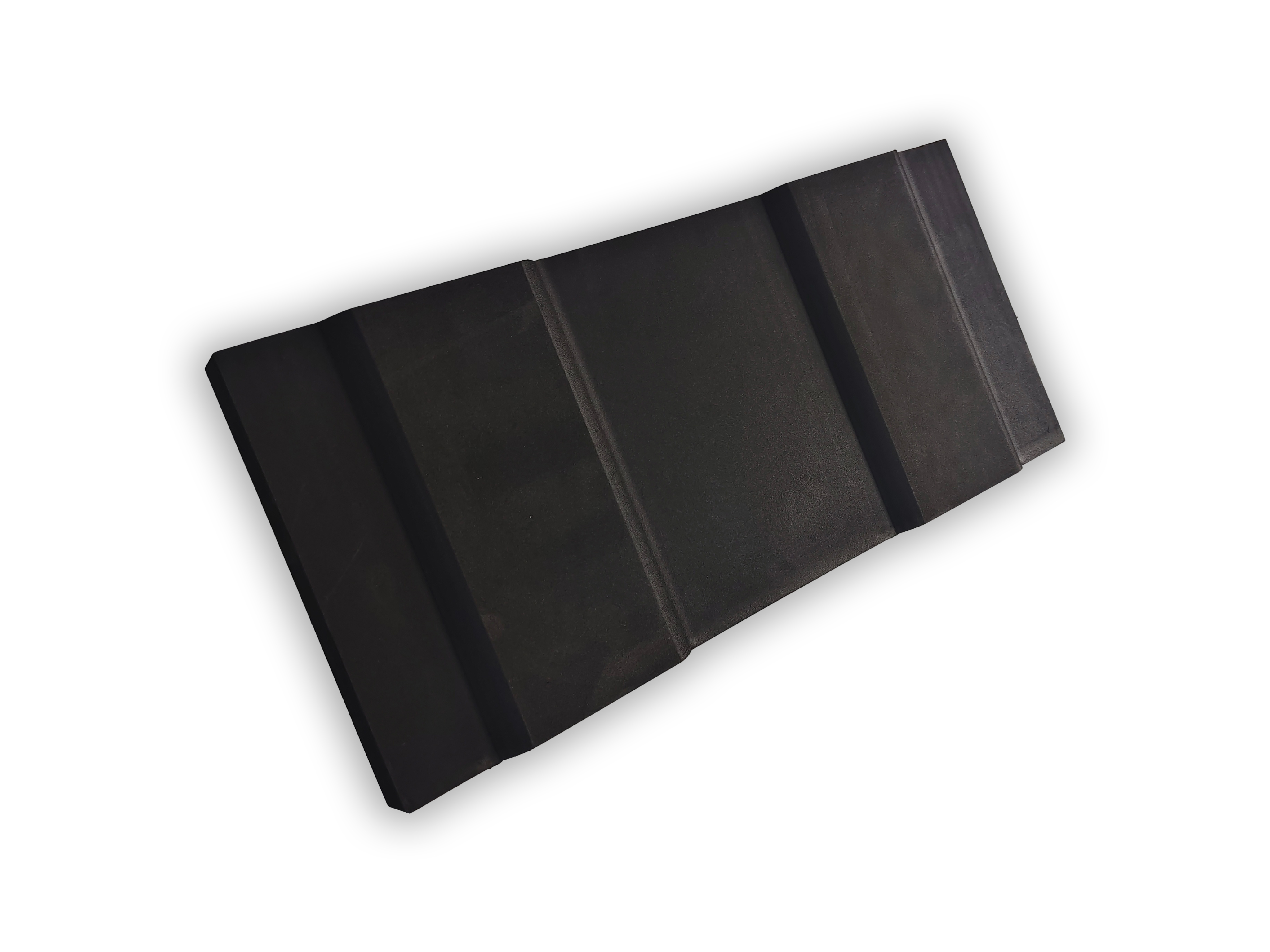

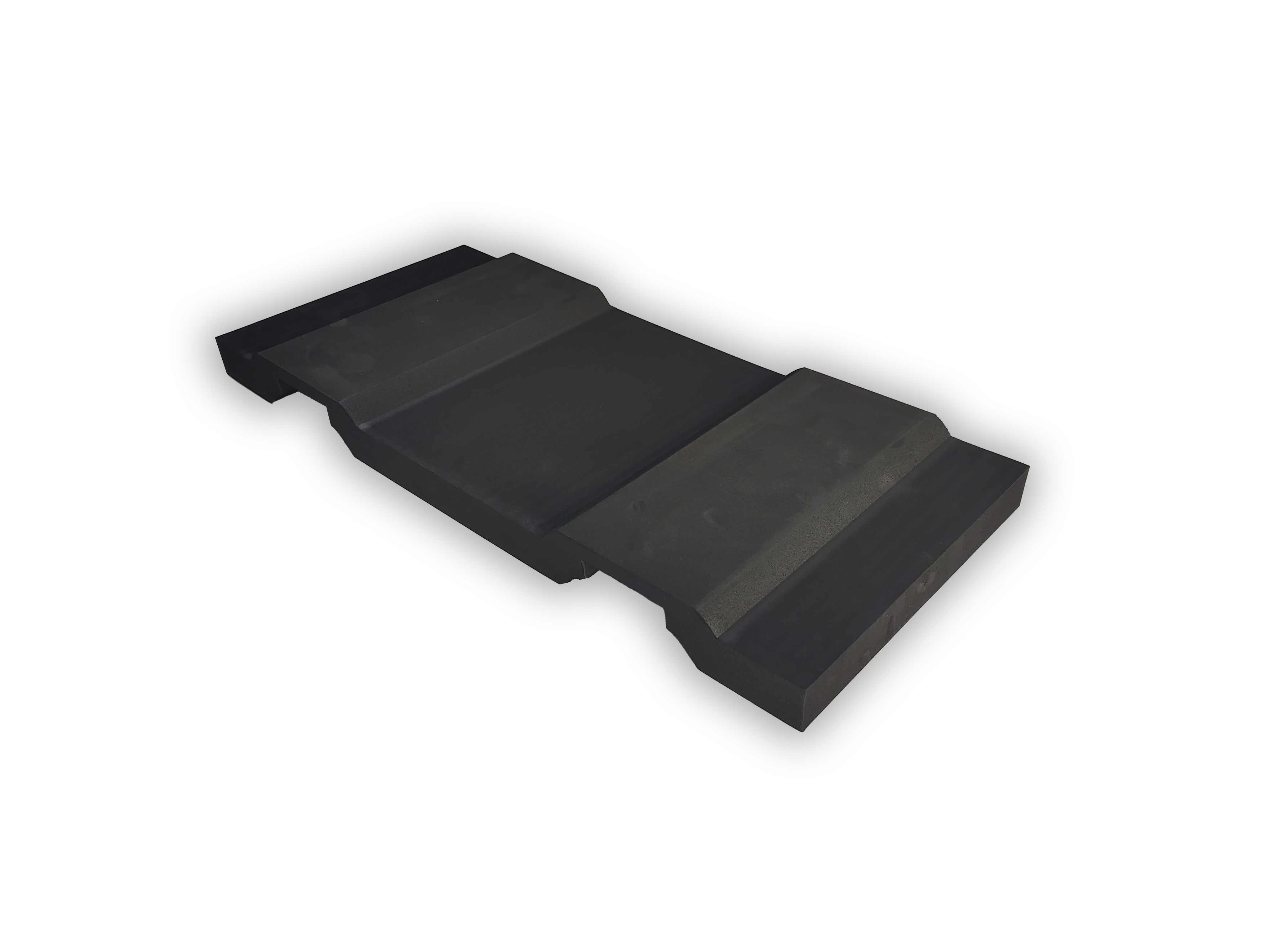

The secret lies in the CNC cutting process. Using advanced computer-controlled machines, we translate your specifications into flawlessly executed cuts, ensuring every contour and cavity aligns perfectly with your gear. This isn’t just about precision—it’s about creating a tailored fit that eliminates movement, protects fragile components, and minimizes wear over time.

Black EVA Foam is the ideal material for this task. Its closed-cell structure resists moisture, chemicals, and compression, while its density provides reliable cushioning without sacrificing durability. Whether you need padding for industrial tools, electronics, or medical devices, our CNC technology allows us to craft intricate designs that standard manufacturing methods simply can’t achieve.

What sets us apart? True customization. From thickness variations to multi-layered inserts, we adapt to your needs. Imagine a foam solution that not only safeguards your investment but also streamlines organization—each tool or component has its own designated spot, reducing handling time and errors.

For businesses prioritizing protection and efficiency, Precision CNC-Cut Black EVA Foam isn’t just packaging—it’s peace of mind. Your equipment deserves more than a one-size-fits-all approach.