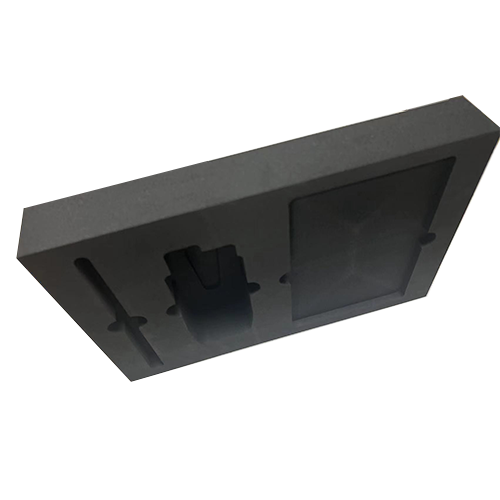

Free proofing, can customize the material, color, size, appearance shape

What is the EVA lining engraving process? In fact, it can also be understood from the surface, that is, the use of CNC engraving machine to process and form,

EVA foam products to achieve the effect that customers need. However, the difference between this process and the ordinary process is that the ordinary is the opening die stamping,

and the product must be pierced when it is punched. Then we flush the bottom, and then we attach it manually. If there are different heights inside the product, it is necessary to take the waste out,

and then process and cut different thicknesses, and then backfill it. Such a process is more troublesome, and it is not formed in one body, resulting in an unattractive effect.

CNC engraving integrated molding, according to the size of the product, size, thickness, depth, the use of programming process, to make the corresponding program,

and then use the foam material processing, there are many CNC tools on the machine, and then the tool according to the program to carve the foam product, so as to achieve the customer needs of the product. In this way, the process is simple and the overall look is high-end and beautiful. But it just costs a little more.

Environmentally friendly EVA foam packing lining - for the automotive stationery and gift industry

Material: Eco-friendly high-density EVA FOAM at the bottom

Color: solid black

Characteristics: Anti-static index 6-9, fire prevention and flame retardant V-2 grade

Density: 38 degrees

Production process: CNC engraving molding

Overall size: 5008*40*20MM

Certificate: Black EVA SGS Certificate, flame retardant certificate, ROHS certificate

Can be customized according to customer requirements size and color, material, free sample, proofing 2 days to complete, batch shipment 3-5 days.