Comprehensive Guide to EVA Foam Sizes: Custom Solutions for Every Need

2025-05-20

EVA (ethylene-vinyl acetate) foam is a versatile material widely used in packaging, sports equipment, industrial applications, and more. One of its key advantages is the ability to customize sizes to meet specific requirements. Below, we outline the standard and customizable dimensions of EVA foam to help you select the best option for your project.

Standard Sizes of EVA Foam

EVA foam is typically available in the following standard sizes, which can serve as a starting point for customization:

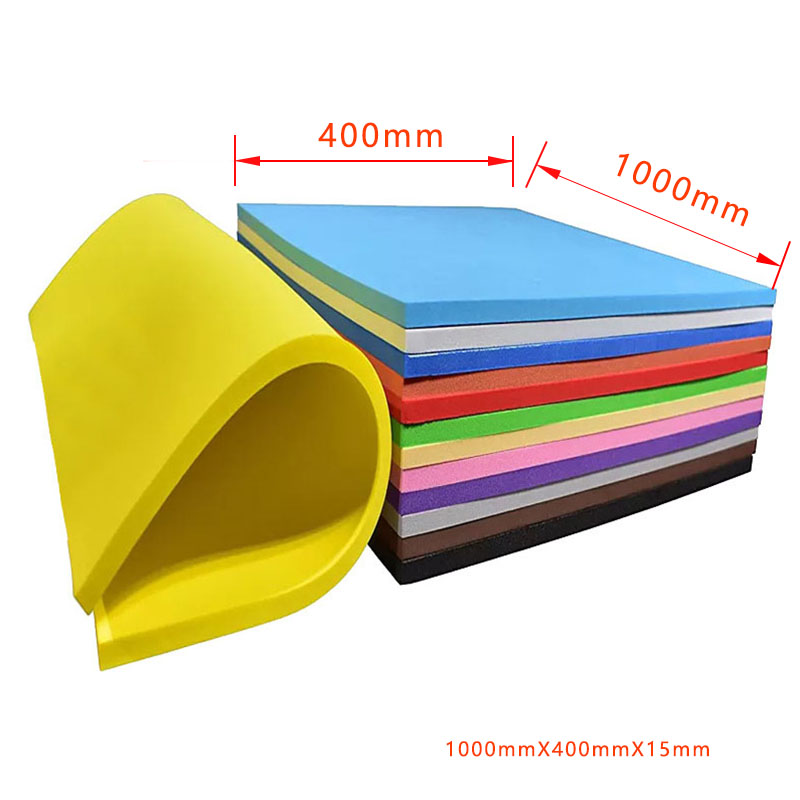

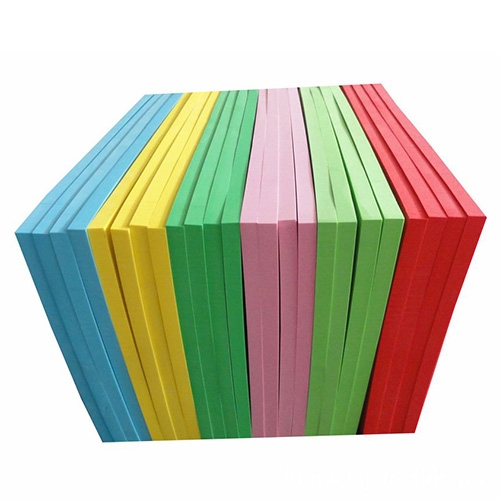

Sheets:

Thickness: 1mm to 50mm (common sizes: 2mm, 5mm, 10mm, 20mm).

Width: 1m to 1.5m (standard rolls or sheets).

Length: Customizable, often sold by the meter or as pre-cut sheets (e.g., 1m x 2m).

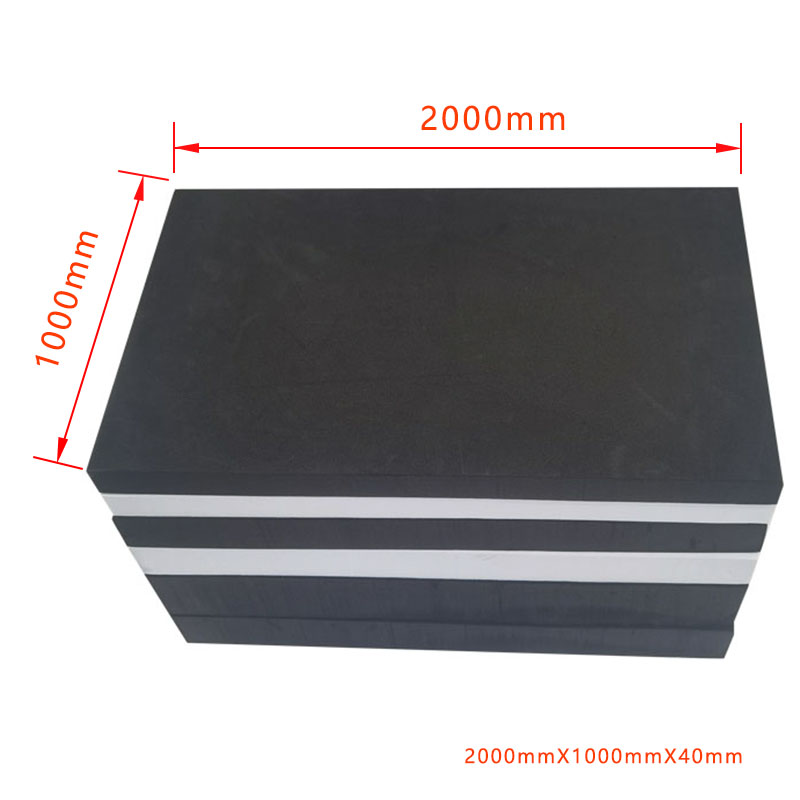

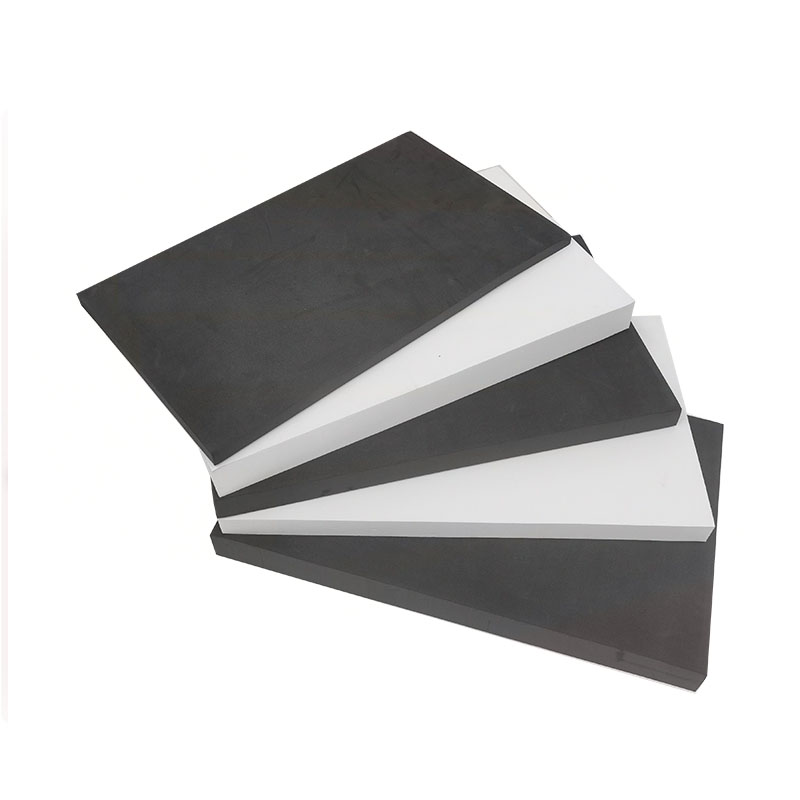

Blocks:

Thickness: 10mm to 100mm.

Width/Length: 500mm x 500mm, 1m x 1m, or other standard sizes.

Pre-Cut Shapes:

Circles, squares, or rectangles in various dimensions (e.g., 50mm diameter, 100mm x 100mm squares).

Customizable Dimensions

For specialized applications, EVA foam can be tailored to exact specifications:

Thickness Variations: Adjustable from ultra-thin (0.5mm) to extra-thick (up to 200mm) for specific cushioning or structural needs.

Large-Scale Sheets: Widths up to 2m and lengths up to 10m for industrial or architectural uses.

Complex Shapes: Precision-cut into irregular or contoured designs (e.g., packaging inserts, gaskets) using CNC or laser cutting.

Factors Influencing Size Selection

Application: Thin foam (1–5mm) for lightweight padding; thick foam (10–50mm) for shock absorption.

Material Density: Higher-density foam (e.g., 60–80kg/m³) offers better durability for heavy-duty use.

Production Efficiency: Standard sizes reduce costs, while custom sizes optimize performance.

Why Choose Custom Sizes?

Custom-cut EVA foam ensures perfect fit and functionality, whether for protective packaging, sports gear, or industrial components. Our advanced cutting technology guarantees precision and consistency, even for complex designs.