Crafting Excellence: The Art of EVA Foam Manufacturing

2025-02-20

At Fubo Packaging Products Co., Ltd., we take pride in revolutionizing the EVA foam industry with our cutting-edge manufacturing processes and unwavering commitment to quality. EVA foam, known for its versatility, durability, and lightweight properties, is a material of choice across various industries, from footwear and sports equipment to automotive and packaging. Here’s a glimpse into how we craft EVA foam to perfection, setting us apart from the competition.

1. Precision in Material Selection:

Our journey begins with the careful selection of raw materials. We source only the highest-grade ethylene-vinyl acetate (EVA) resins, ensuring that every batch of foam meets our stringent quality standards. By partnering with trusted suppliers, we guarantee consistency and reliability in every product we produce.

2. Advanced Blending Techniques:

The secret to our superior EVA foam lies in our proprietary blending process. Our state-of-the-art mixing technology allows us to achieve the perfect balance of EVA resin, foaming agents, and additives. This meticulous blending ensures that our foam exhibits exceptional elasticity, resilience, and resistance to wear and tear.

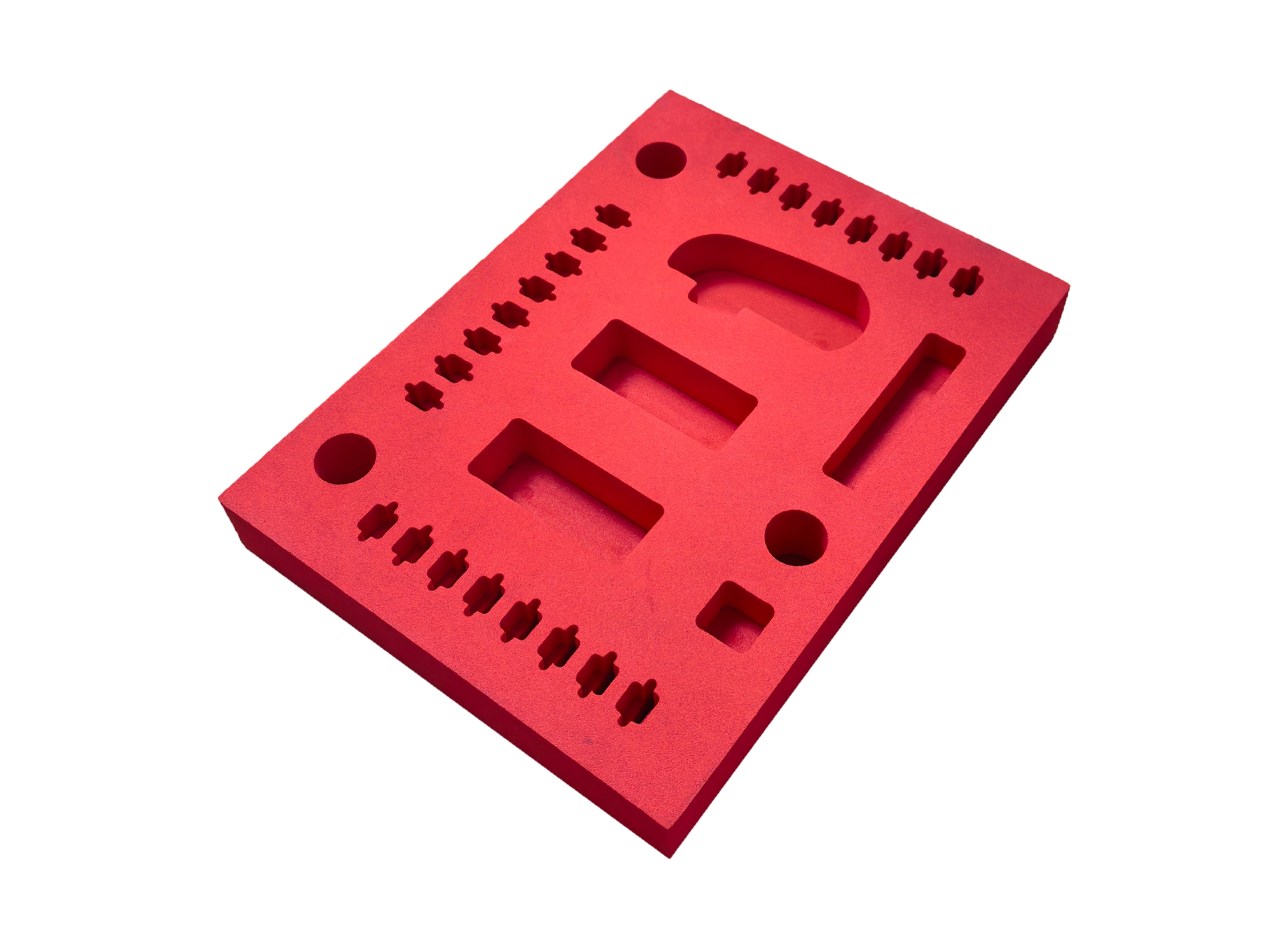

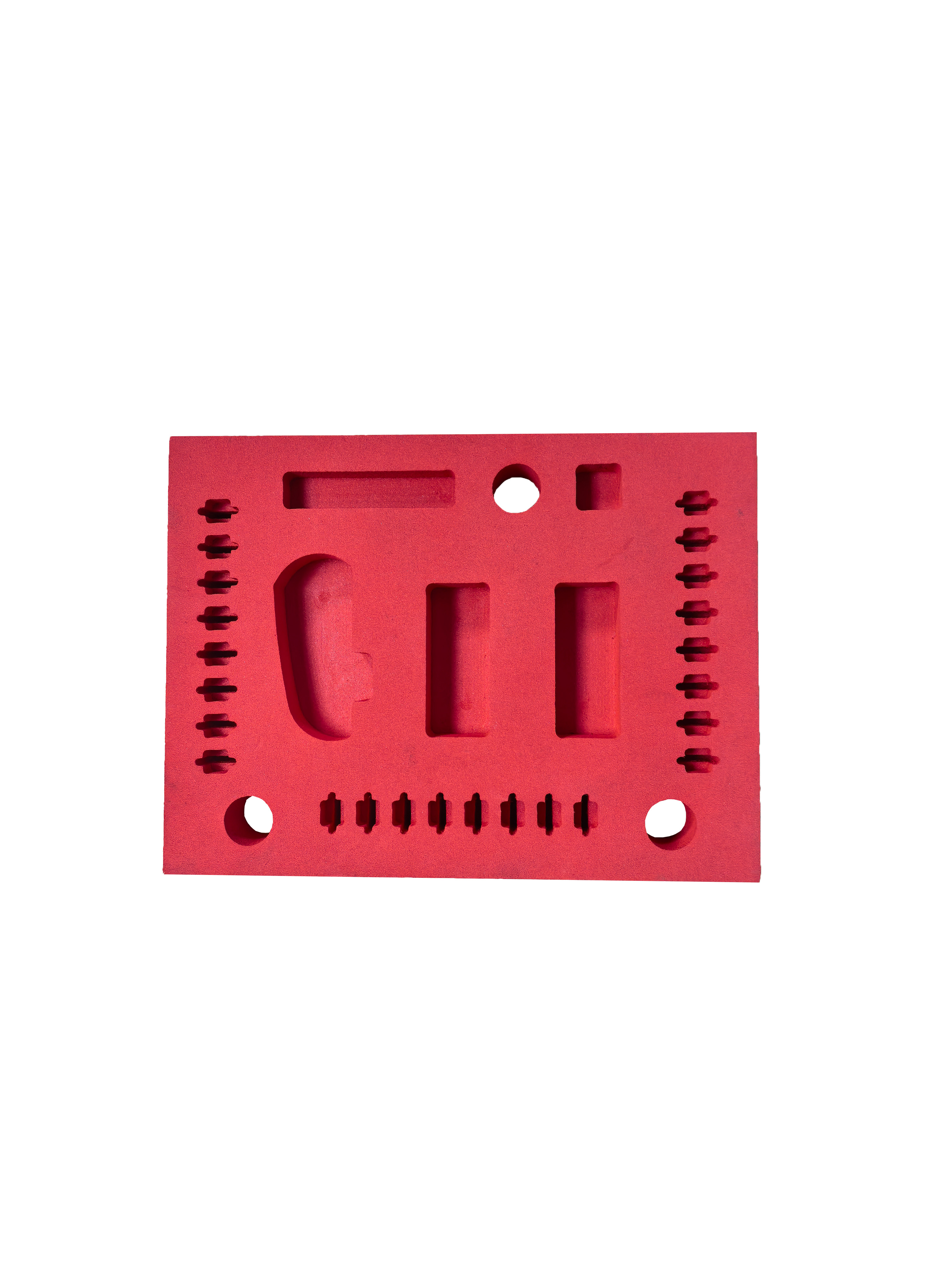

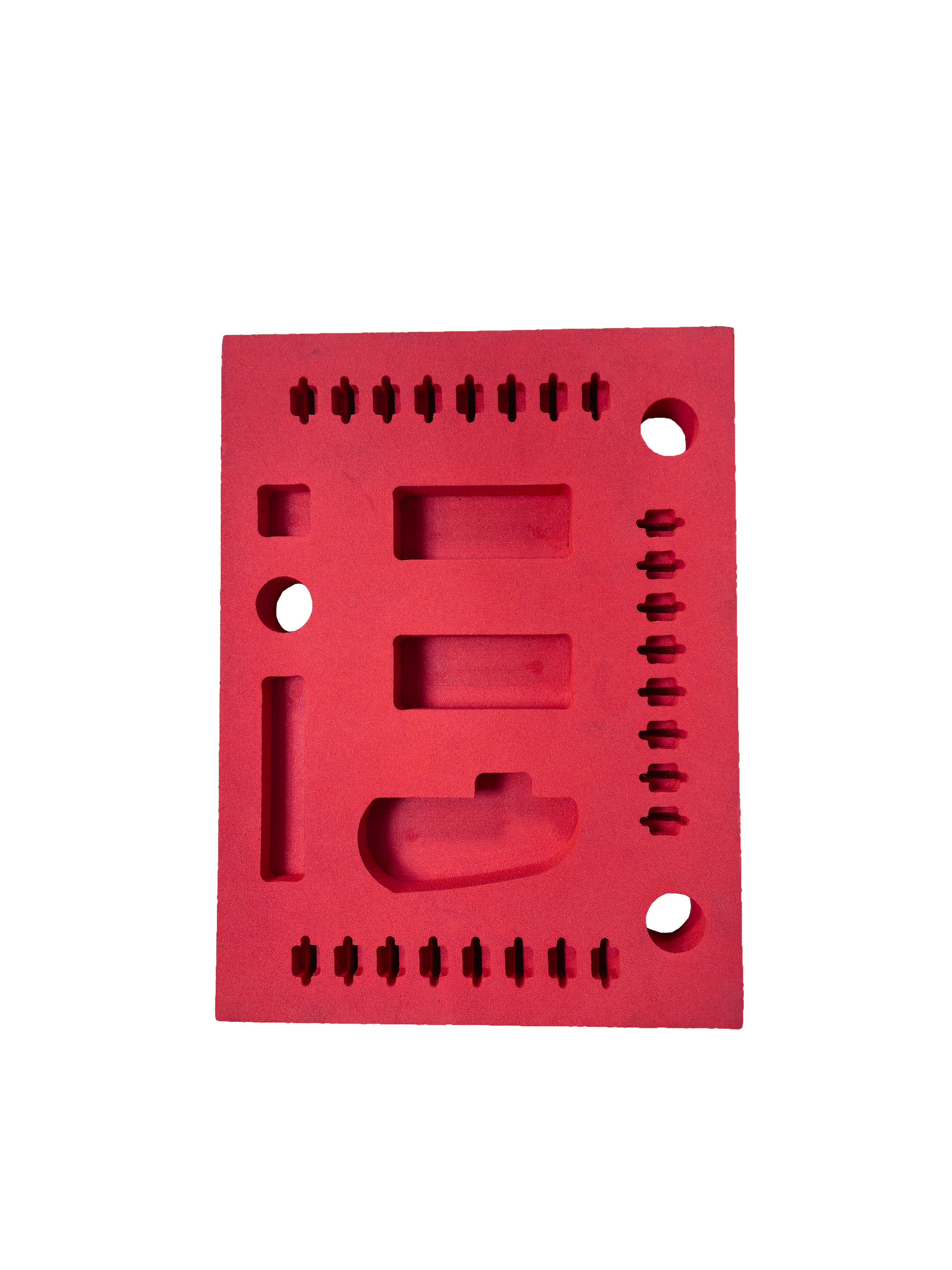

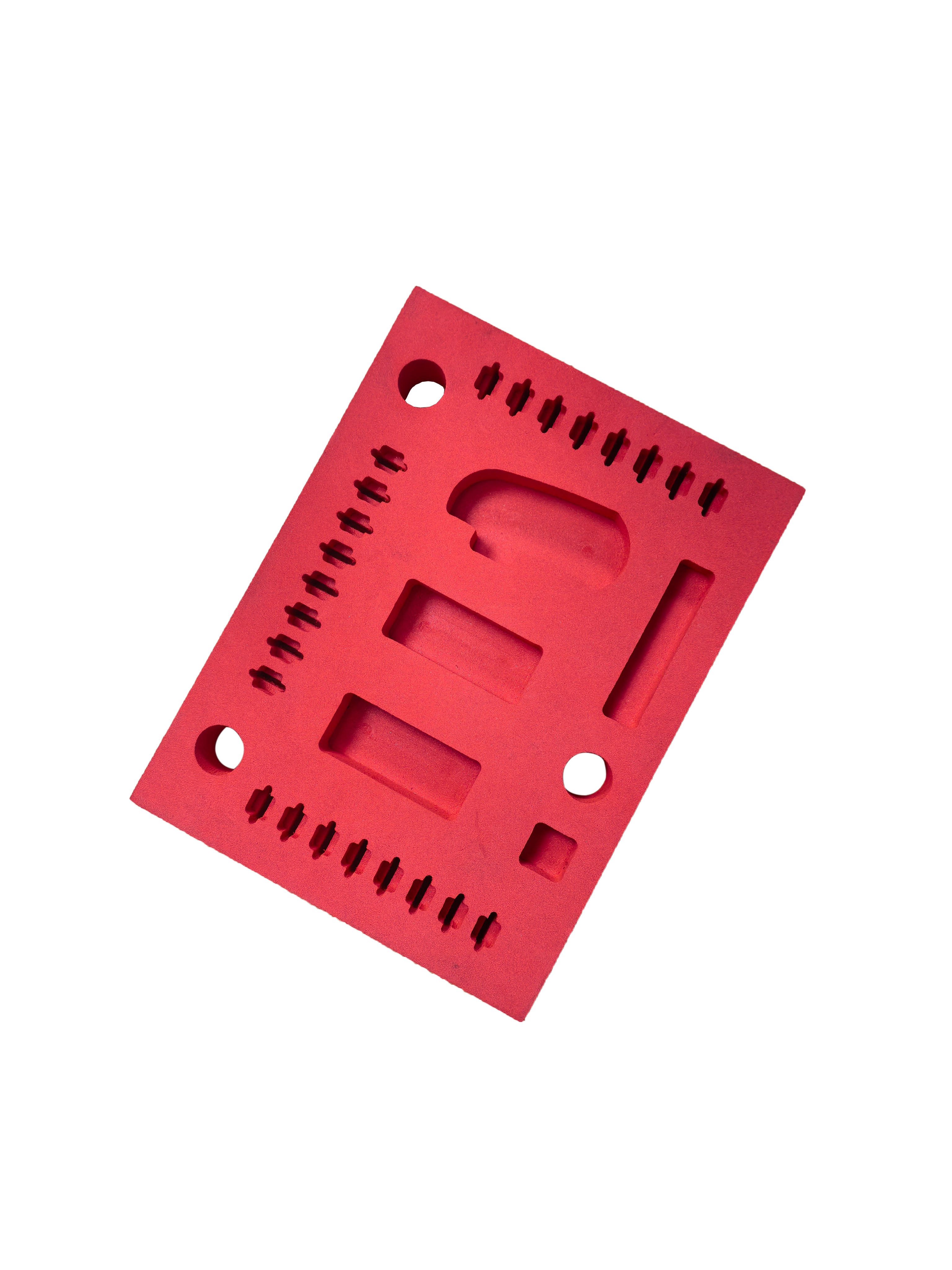

3. Innovative Molding and Curing:

Our advanced molding and curing techniques are at the heart of our manufacturing process. Using precision molds, we shape the foam into various forms, catering to the specific needs of our clients. The curing process, carried out in controlled environments, enhances the foam’s structural integrity and ensures uniform density throughout.

4. Customization at Its Best:

Understanding that every application has unique requirements, we offer unparalleled customization options. Whether it’s adjusting the foam’s density, hardness, or color, our team works closely with clients to deliver tailor-made solutions. Our ability to produce EVA foam in a wide range of specifications is a testament to our flexibility and expertise.